|

|

|

| Mica |

|

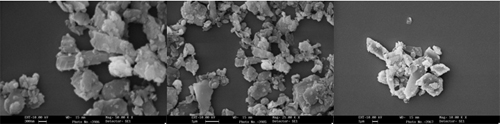

| MICA-BM POWDER IMAGES @ 300nm & 1um scale |

Mica-PACM powder image @ 1um scale |

|

| Chemical compositions |

| Composition by wt% |

|

| Al2O3 |

26.980 |

| TiO2 |

------ |

| CaO |

00.425 |

| MgO |

01.935 |

| K2O |

09.245 |

| Na2O |

01.230 |

| Fe2O3 |

01.350 |

| L.O.I. |

03.210 |

| Colour White |

+70-75, 80-85 |

Particle sizes See images for size, shape and spotless properties

|

Spotless/with spot +1/2" size scrap,20-120mm flakes,100-600 mesh fine and micronized powder |

| Important notice regarding this information- Mica is a naturally occurring raw material & its composition mentioned above is expected to vary The statements and technical information contained in this document are based on our research and research of others. However, this document is not contractual, and nothing in it, constitutes a warranty (expressed or implied) that the goods described are accurate and fit for a particular purpose of the customer. Purchasers are advised to make their own tests to determine the suitability. This specification supersedes any former publication and is subject to change without notice. |

|

| |

| Applications of Mica |

| Indian Micronized Mica for paints and coatings, cosmetics, rubber, plastic and polymer formulations. |

| |

Micronised Muscovite Mica is pigment extender in various paints and coatings & regarded tough, flexible and transparent.

Mica is an anti-friction, anti-fouling, anti-settling, anti-corrosive, anti-tarmish and anti-siege agent. The over lapping layers of mica platelets form a tough shield that improves paint integrity and durability.

Mica acts as a reinforcing pigment to reduce cracking, peeling and checking in the dry film and prevents shrinkage and sheering of the paint. When a paint starts to fall, mica holds it together sufficiently to keep it away from cissing, curtaining and prevents microscopic ruptures in the paint films.

Mica particles brighten the tone of the coloured pigments, at the same time, transmit and reflect light resulting in proven decorative effects and design. It increases the gloss of paint more effectively than spherical or irregularly shaped filler particles of an equivalent size product. Mica also optimize the effect of other pigments by ensuring that the pigment particles are evenly spaced in the dried paint film.

Mica is an inert material and thus easily resist actions of light, heat, temperature, electricity, water, acids, and alkalis, as well as, it reduces hydrolytic and electric action within paint film. Mica also imparts resistance to penetration of destructive sun-rays, moisture, atmospheric gases and decreases blistering and staining from the substracts. It prevents degradation of paint films by ultra-violet (UV) radiation, absorb UV rays and improve paint durability by retarding the oxidation process.

Mica is also compatible with all pigments and is easily wetted with oils, thinners, water or emulsions and other liquid vehicles. Because of its high specific gravity mica particles tend not to settle but stay uniformly dispersed in a liquid paints. Mica particles become evenly dispersed throughout the paint film and lying flat against each other they could easily take stresses and strains set up within the paint film as it ages. Mica fillers disperse well in both oil and water based paints and suitable for a high speed mixing plants.

As mica has good suspension properties, its inclusion reduces running, sagging and settling of paints, as well as, improves weather ability and brush ability. The addition of mica makes it possible to redisperse the settled pigment easily at any stage of production by simple stirring.

Mica is widely used in Aluminum, automotive, anti corrosive, cement, emulsion, synthetic, water, fire resistant, marine, road marking, textured, traffic paints.

Muscovite mica reinforces the paint film during drying and curing. Mica Reduces internal stress caused by oxidation, thermal expansion & contracting. Mica Improves the paint film’s flexibility. Mica Improves mud crack resistance. Muscovite mica provides excellent barrier protection. Mica flakes align parallel to the substrates. Mica flakes imparts glitter effect in water based Decorative Paints, Protective & OEM Coatings Mica Provides low moisture & gas permeability. Mica Improves stain resistance. Muscovite mica’s high aspect ratio provides beneficial rheological properties & Improved sag resistance. Mica near the surface of the coating protects the system by reflecting harmful radiation. Mica improves weathering and UV degradation resistance characteristics. Coarse mica flakes can provide an aesthetic appeal (glitter effect).

Mica also finds applications in cosmetic, paint and coatings, rubber, electronics, plastics and polymers, refractory, insulation, metallurgical formulations.

Mica powders are available in dry and wet ground as well as in micronized particles, whiteness / brightness and coarse flakes as per the specific requirements of buyers. |

| |

| Important notice regarding this information |

The statements and technical information contained in this document are based on our research and research of others. However, this document is not contractual, and nothing in it, constitutes a warranty (expressed or implied) that the goods described are accurate and fit for a particular purpose of the customer. Purchasers are advised to make their own tests to determine the suitability.

This specification supersedes any former publication and is subject to change without notice. |

|

|

|