|

|

|

| Zirconia |

| Zirox-CP |

Yttria stabilized Zirconia Powders (ZrO2-Y2O3) Yttria stabilized Zirconia Powders (ZrO2-Y2O3)

Monoclinic Zirconia Monoclinic Zirconia  Tetragonal Zirconia Polycrystal(TZP) Tetragonal Zirconia Polycrystal(TZP)  Fully Yttria Stabilzed Zirconia ( FYSZ) Fully Yttria Stabilzed Zirconia ( FYSZ) |

|

|

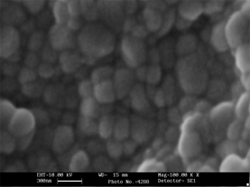

TZY-3nSB Zirconia- Sintered grain

size image @ 300nm |

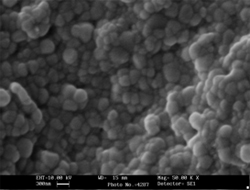

TZY-3nSB Zirconia-

Sintered grain size image @ 1um scale |

(uni-axially pressed & sintered at 1350'c having density of 6.07 g/cc) |

|

Constituents

Grdae wise wt % |

ZM |

ZM-n |

TZY 3 mol% |

TZY-SB |

TZY-3n

nano 3 mol% |

TZY-3nSB |

FZY-8n |

|

|

Monoclinic

Zirconia |

Nano Monoclinic zirconia |

Yttria Stabilized

Zirconia

(Without binder) |

Spray dried

3 mol% Yttria

Stabilized tetragonal

zirconia

with binder |

Yttria Stabilized tetragonal

Zirconia

(without binder)

|

spray dried

Nano 3 mol% Yttria Stabilized tetragonal

Zirconia with binder

|

Nano 8 mol%

yttria Fully

stabilized

Zirconia

|

| ZrO2(HfO2) |

99.9 |

99.9 |

94.80 |

94.80 |

94.80 |

94.80 |

86.15 |

| Y203 |

00.00 |

00.00 |

5.20 |

5.20 |

5.20 |

5.20 |

13.75 |

| Other impurities |

Individually in between 20-100ppm, total < 1000 ppm |

Sintered

grain size |

|

|

500-1500nm |

500-1500nm |

100-500nm

See above images |

100-500nm See above images |

|

Vickers Hardness

HV 10 |

|

|

|

|

+1350 |

+1350 |

|

| Bulk density (gm/cm3) |

00.42 |

|

00.36 |

01.17 |

|

|

0.42 |

| Surface are (BET-m2/g) |

8,15,30 |

8,15,30 |

8 & 15 |

8 & 15 |

8 & 15 |

8 & 15 |

|

| Sintering temp ( 'C, ) |

-------- |

|

1450-1530 |

1450-1530 |

1320-1380 |

1320-1380 |

------- |

Sintered Density

(gm/cc) |

|

|

06.07 |

06.07 |

06.07 |

06.07 |

|

| then please put Bending strength(MPa) |

|

|

1320-1491 |

1320-1491 |

1360-1850 |

1360-1850 |

|

|

Applications : suitable for uniaxial,Cold isostatic.Hot isostatic (CIP/HIP) pressing,injection molding,extrusion,slip casting,tape castings techniques for making dental implants,SOFC (Solid Oxide Fuel Cells),Bio Ceramics,Abrasives,Electronics, Precision

ceramic components,

Polishing, catalysts,coatings,Plastics,zirconia beads,grinding media,lliners,seals,optical fibre ferrules,sleeves,wear resistant parts,structural and textile ceramics,probes,crucibles,wire drawing dies,frction etc applications.

|

| |

| Important notice regarding this information: |

| The statements and technical information contained in this document are based on our research and research of others. However, this document is not contractual, and nothing in it, constitutes a warranty (expressed or implied) that the goods described are accurate and fit for a particular purpose of the customer. Purchasers are advised to make their own tests to determine the suitability. This specification supersedes any former publication and is subject to change without notice. |

|

| |

|

| Team RGe |

RGe may be contacted at its head quarters:

F-8, PHASE III, RIICO INDUSTRIAL AREA, Beawar 305901. Rajasthan – India.

Tel +91 1462 512340, fax +91 1462 226966, Mobile +91 9414009700

Email: ssr@zirox.co.in, zirox50@gmail.com .

Website: www.zirox.co.in |

| |

|

|